Establishing A Labeling Program For A Large Scale Energy Provider

A Partnership Between Marking Services, Inc. & Southern Company

For 20 years, Southern Company has partnered with Marking Services, Inc. (MSI) to develop a comprehensive labeling

and asset management program using MSI’s identification products and services.

Southern Company’s family of companies is proud to deliver clean, safe, reliable, and affordable energy to their 9 million customers across the Southeast and beyond. Every day, their employees carry out their jobs with a customer-focused approach and service excellence. They do this through electric operating companies in 3 states and natural gas distribution companies in 4 states.

The Challenge

Due to the critical nature of generating and delivering energy, it is imperative that Southern Company completes its projects promptly to guarantee a reliable energy supply. While doing this, they also need to prioritize safety, support operations, maintenance, and emergency response. Southern Company needed a labeling and asset management program that could help them achieve project deadlines, support plant operations, and maintain safety in a timely manner.

The Solution

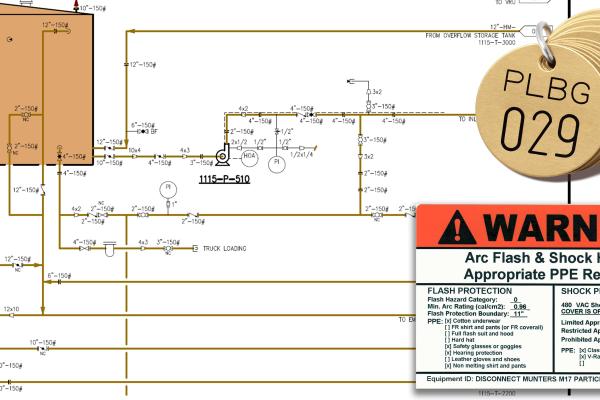

In a strategic partnership, MSI and Southern Company worked together to establish a labeling and asset management program that delivers engineering services and customized labeling solutions such as durable QR-coded equipment tags, valve tags, and pipe markers. MSI designed these products to withstand the elements within operating environments at Southern Company’s facilities. This innovative collaboration encompasses the supply of line lists, updated P&IDs, fi eld surveys, installation services, and pack-by services, as well as the products listed above.

We wanted everything uniform so our training instructions for operating, maintenance, and lockout/tagout tasks could all call out the same tag. This sounds like a very simple thing to do, but it’s not all that common in our industry.

Example 1: Designing & Installing Durable Labels For Electric Generating Plants

MSI partnered with Southern Company to create a standardized labeling system in over 20 electric generating plants which included several solar & hydro energy facilities. This partnership started with MSI utilizing Southern Company’s P&IDs and facility site plans to create line lists, ensuring accurate counts of labels needed as well as accurate installation points.

Collaborating closely, MSI developed specialized products tailored to meet the demands of Southern Company’s electric generating plants. These products were engineered to exhibit exceptional durability to withstand the operating environments of these plants. Additionally, they needed to be utilized in day-to-day lockout/tagout tasks, operating procedures, applications, and maintenance work.

To address piping requirements, MSI designed durable MS-995 Carrier and Coiled Pipe Markers. Simultaneously, for valve and equipment, MSI designed durable, fully custom Laser Engraved Stainless Steel and MS-215 Thermoplastic Tags that included QR codes to be utilized for procedures in the field.

In addition to product development, MSI extended its support with installation services for the pipe markers provided at several electric generating plants. MSI’s field team ensured proper and precise installation which in turn saved Southern Company time and labor, aiding in the achievement of meeting project deadlines.

- Product Types: MS-215 Rigid Thermoplastic QR-Coded Tags, Stainless-Steel QR-Coded Tags, MS-995 Coiled Pipe Markers, and MS-995 Curved Carrier Pipe Markers.

- Services Rendered: Custom Product Design, Pack-By, Engineering, and Installation.

- Quantity: 500,000+

- Operating Environment: Outdoors, high heat, strong winds, and exposure to dust from limestone and gypsum.

The tags have been here for 20 years and still look new.

Example 2: Meeting Regulatory Requirements & Enhancing Project Efficiency For PSM Systems

In environments where ammonia is regulated, Southern Company mandates that its PSM tags stand out distinctly among other tags.

Collaborating closely with Southern Company, MSI designed a durable MS-215 Thermoplastic Tag capable of enduring the conditions in regulated ammonia environments. The tag featured a base color complemented by a red border, ensuring clear differentiation, while also maintaining uniformity with non-PSM tags. Moreover, they were equipped with QR codes to utilize for lockout/tagout tasks, operating procedures, and maintenance work.

To streamline the PSM tag ordering process, MSI designed custom order forms to be filled out by Southern Company and submitted to MSI. This enhanced efficiency and ensured label uniformity across plants.

Once custom order forms were completed and tags were produced, MSI packed them in accordance with Southern Company’s specifications to optimize installation. Concurrently, delivery schedules were managed by MSI to coincide with Southern Company’s project schedule. All of this ultimately aided Southern Company in achieving internal compliance while meeting project deadlines.

- Product Types: MS-215 Rigid Thermoplastic QR-Coded PSM Tags.

- Services Rendered: Custom Product Design, Engineering, Custom Order Forms, and Pack-By.

- Quantity: 5,000+

- Operating Environment: Outdoors, high heat, and regulated ammonia.