Best Practices for Labeling Services in Advanced Project Delivery

Labeling in Advanced Project Delivery Whitepaper

Nov 10, 2025

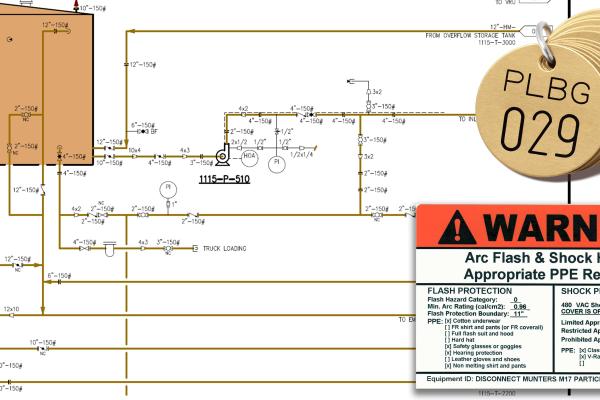

This whitepaper demonstrates how integrating industrial labeling and asset identification early in the project lifecycle, starting from Front-End Loading (FEL) through Operations & Maintenance (O&M), can significantly reduce risk, rework, and delays in capital projects.

MSI’s approach aligns labeling with Advanced Project Delivery (APD) and Advanced Work Packaging (AWP) principles, supporting safety, regulatory compliance, and digital integration. The use of QR-enabled labels creates a digital thread, connecting physical assets to their digital representations and empowering connected workers with real-time data access and mobile workflows.

The Challenge

Labeling is often treated as a late-stage procurement detail, leading to inconsistencies, compliance failures, and incomplete digital handovers. The whitepaper highlights the risks of this reactive approach and advocates for early, engineered labeling strategies to support project execution, safety, and digital readiness.

The Solution

MSI’s Solution

MSI offers a lifecycle-driven, standardized labeling solution that integrates asset identification into the core execution model of AWP. Key elements include:

- Early engineering takeoffs and field surveys

- Specification development for compliance

- QR-code-enabled labeling for real-time tracking

- Turnkey installation and asset management integration

This methodology is industry-agnostic and has been successfully applied to data centers, pharmaceutical facilities, oil & gas installations, chemical plants, food and beverage plants, semiconductor facilities, hospitals, power generation projects, manufacturing facilities, and offsite modular fabrication shops.